Hot sale pasta macaroni food extruder

Hot Sale pasta macaroni food Extruder is produced by single-screw extruder through extruding cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the maxaroni pasta needs frying to get expanded.

Short pasta macaroni machine

Raw material:Wheat four

Product: short cut pasta macaroni

Capacity:60kg/hour, 150kg/hour and 300kg/hour

Machine material: SUS304

Screw Material: 38CrMoAl, Alloy steel

Product description

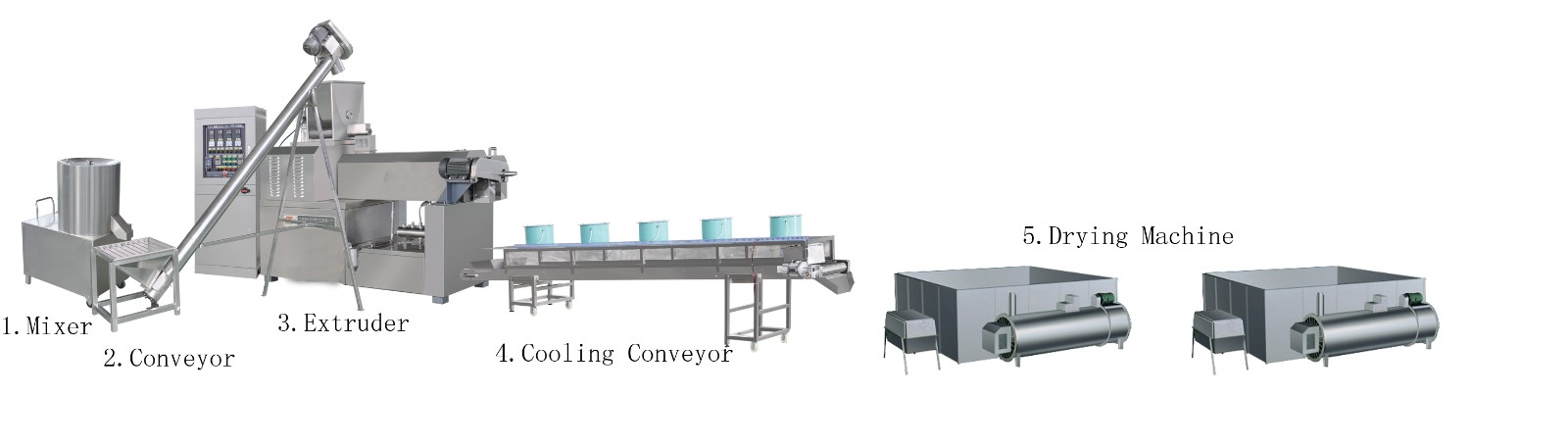

pasta macaroni machine photo:

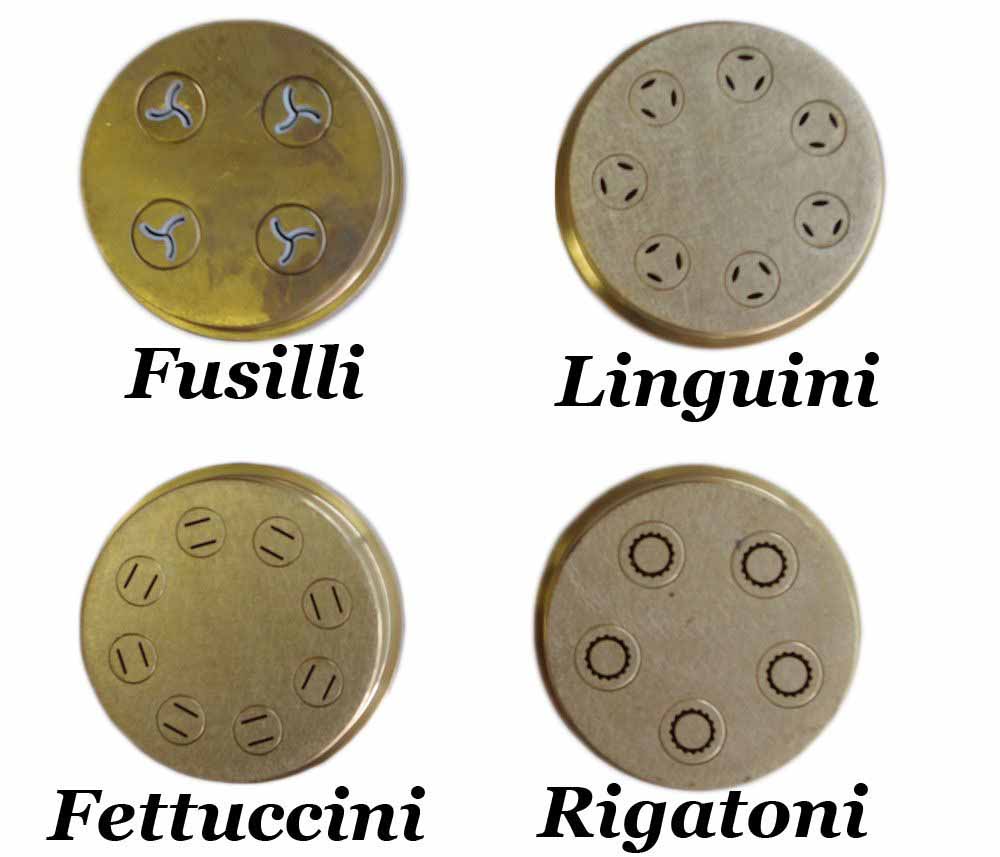

As one of our main products, short pasta macaroni machine has researched and developed with over 20 years. The short pasta macaroni machine can produce various shapes of pasta macaroni food, such as shell, fusilli and so on. Customer can choose the suitable shapes of mould.The single screw extruder is durable enough to use for a long time. The short pasta macaroni machine is exported to many countries in Asia and South America.

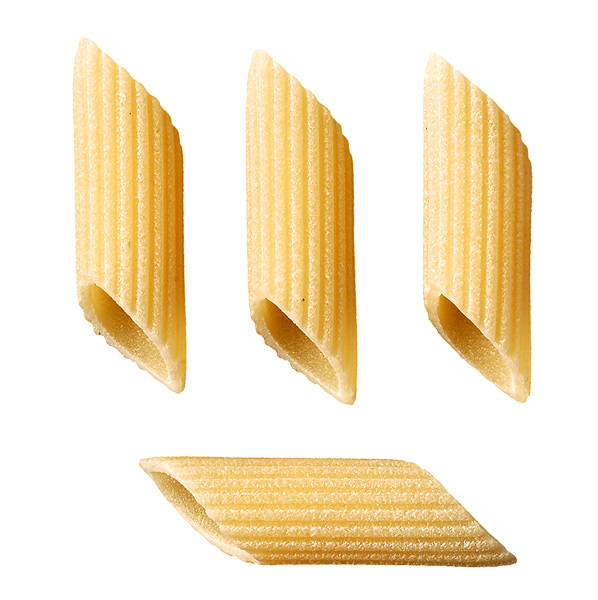

Short cut pasta macaroni sample:

Here are some samples of products produced by short pasta macaroni machine.

Pasta macaroni machine parameter:

Model | Install Power | Real Power | Capacity | Dimension |

DLG80 | 70KW | 50KW | 60-70kg/h | 15x 2.0 x 3.0 |

DLG110 | 105KW | 73KW | 120-150kg/h | 22x 2.0 x 3.0 |

DLG150 | 190KW | 135KW | 250-300kg/h | 30x 2.0 x 3.0 |

There are three kind of capacity of short cut pasta macaroni machine.

Different dies for different shapes pasta:

Product process:

The process of short cut pasta macaroni machine are as follows:

Mixer: To mix the raw material such as corn flour, water and so on.

Extruder: Short pasta macaroni machine use durable single screw thus can use a long time. There has vacuum system on the extruder to produce high quality pasta without air bubble. The extruder is produced with stainless steel.

Dryer: The multiple layer dryer can save much space in factory. It can

dry the pasta with high efficiency with the “s” layer inside. The dryer is made by stainless steel.

Application:

The short pasta macaroni machine can produce short cut pasta macaroni food with various shapes.

Service:

*Consultation service before, during,and after sales;

*Project planning and design service;

*Debugging of equipment until everything is functional;

*Management of equipment' long distance shipping from seller's factory to the named place by buyer;

*Training of equipment maintenance and operating personally;

*New production techniques and formulas;

*Provide 1 year complete warranty and life-time maintenance service.

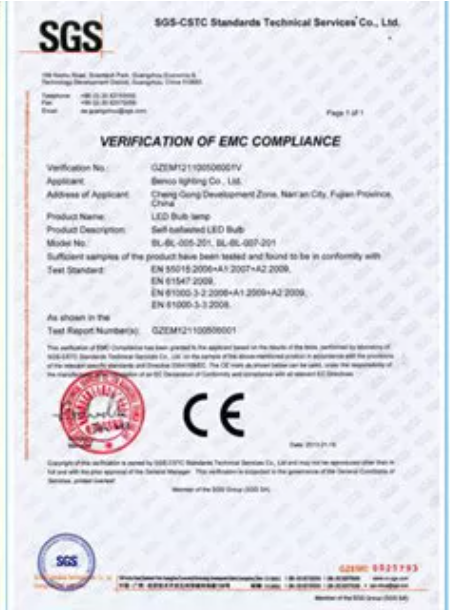

Certificiations

Related Products

Related News

Submitted successfully

We will contact you as soon as possible