The Single Screw Extruder

It is suitable for making the Non-Puff product.

1. Product: Pasta macaroni,Dog Chews,Fried Pellets

2. Capacity: 100kg/hour,150kg/hour, 300kg/hour

3. Screw material: 38CrMoAl and CrMo12V Alloy steel

Product Features:

1. Automatic temperature control system

2. Automatic raw material feeding system

3. Extrusion system is made by Single screw with the main motor and gear box.The screw is alloy steel. The speed of the Motor is controlled by Inverter.

4. The cutting system is made by the cutting blade and Cutting motor. The cutting speed is controlled by Inverter

5. For Pasta making there is important system “Vacuum system” for producing quality pasta

Product Features:

1. computerized temperature control system

2. automatic uncooked fabric feeding gadget

3. extrusion machine is made via unmarried screw with the main motor and gear box.the screw is alloy steel. the rate of the motor is controlled by way of inverter.

4. the reducing machine is made by the reducing blade and cutting motor. the reducing speed is controlled by inverter

5. for pasta making there is vital machine “vacuum system” for generating excellent pasta

It is suitable for making the Non-Puff product.

1. Product: Pasta macaroni,Dog Chews,Fried Pellets

2. Capacity: 100kg/hour,150kg/hour, 300kg/hour

3. Screw material: 38CrMoAl and CrMo12V Alloy steel

Dog Chews made by Single-Screw Extruder

Pasta macaroni made by Single screw Extruder:

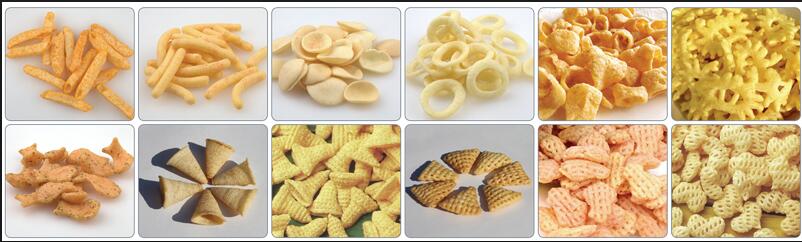

Fried Pellets snack made by single screw extruder:

Product Parameters:

Single screw Extruder Parameters:

Model | Install Power | Capacity | Dimension |

DLG100 | 37KW | 100-120kg/h | 2.5x 0.85x 2.0 |

DLG110 | 37KW | 150kg/h | 2.6x 0.9 x 2.0 |

DLG150 | 100KW | 300kg/h | 3.8x 1.3 x 2.2 |

Application and After-Sales Service:

The Single screw Extruder is used for Non Puff Snack food production industry.

“Saibainuo Machinery” provide the great Service to help our customers set up their project

Before Sales:

1. We provide the drawing design according to customer workshop

2. We provide the formulation

3. We provide the cost analysis

4. We trail ran Pet Food Machine for customers

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Provide the upgrade on machines

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible