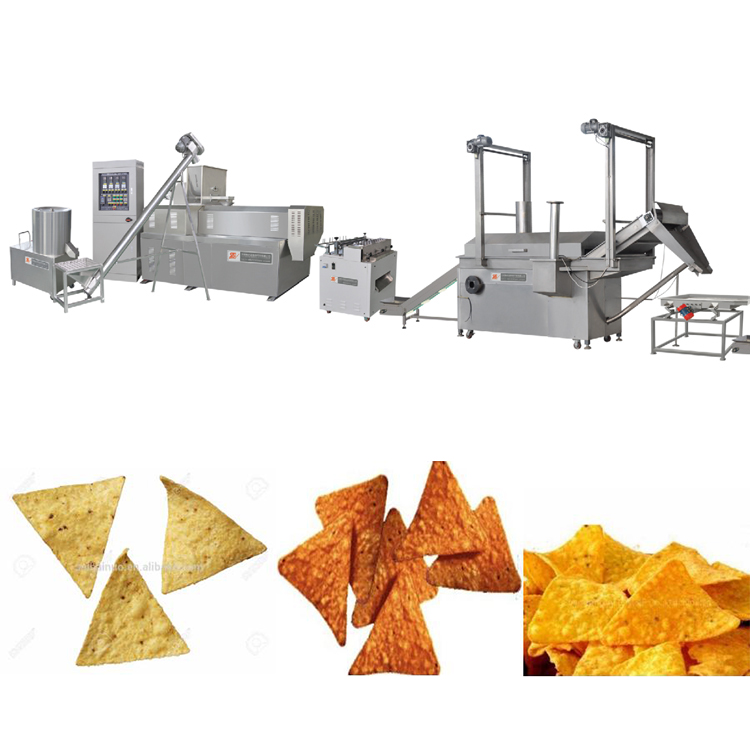

Corn Flour Nacho Chips Machine

Corn chips machine

Raw material: Corn flour

Machine material: SUS304

Electric Parts brand:SIEMENS

Product: Corn chips,Nacho chips

Product description:

Corn chips gadget is produced with the aid of using corn flour. The corn chips gadget can produce crispy and engaging chips that's welcomed with the aid of using customers. Equipped with dual screw extruder, the meals may be extruded with better stress for this reason generating excessive best meals. The more than one layer dryer can shop a good deal area in manufacturing facility with excessive efficiency. The non-stop fryer will fried the meals making it a good deal crispy.

Raw material: Corn flour

Machine material: SUS304

Electric Parts brand:SIEMENS

Product: Corn chips,Nacho chips

Corn chips machine parameter:

There are three kind of capacity of corn chips machine.

Model | Capacity | Power | Work area |

SLG65 | 120-150KG/H | 120KW | 100㎡ |

SLG70 | 200-220KG/H | 150KW | 120㎡ |

SLG85 | 300-350KG/H | 200KW | 150㎡ |

Products sample:

Here are some samples of products produced by corn chips machine.

Products process:

The process of corn chips machine are as follows:

Mixer: To mix the raw material such as corn flour and other powder.

Extruder: Twin screw extruder is used to extrude and cook raw material into different size and shapes. The gear box has forced lubrication system. All motors can be adjusted the speed by Inverter.

Cutting: Cut the product into the shape

Fryer: To fry the food with oil. The speed and the temperature can be adjusted. There is oil filter to clean the oil.

Flavoring machine: Scatter the seasoning powder on the food. The roller will mix the oil and seasoning powder evenly to make food tasty.

Application:

The corn chips machine can produce crispy and tasty corn chips snack food.

Service:

Pre-sale services

1).Provide professional advisory services

2).Communicating with customer and learn your requirement

3).Welcome to visit our factory

Services during the sales

1).Confirm every terms and details and sign contract with customers

2).Inspect the machine before leaving the factory.

3).Packing machines and delivery on time

After-sale services

1). Provide installation, commissioning and training

2). Provide necessary technical support and update information

Related Products

Related News

Submitted successfully

We will contact you as soon as possible