Fried Bugle Making Machine

Raw material: Wheat Flour

Machine material: SUS304

Electric Parts brand: SIEMENS

Product: Fried Bugles,Corn chips,Nacho chips

The fried bugles machine can produce different shapes of fried snack food with various shapes of mould.

*The high automation machine requires easy operation.

*The twin screw extruder is durable for long time usage.

*The dryer has multiple layer which saves much space in factory.

Products description:

Fried bugles machine is one of fried snack food researched and developed by our company. The raw material can be corn flour, potato starch, wheat flour and so on. The fried bugles snack food can be flavored with tomato powder, cheese powder, BBQ powder and so on to make it tasty and suitable for more customers. The fried bugles machine has been exported to many countries with high appreciation.

Fried bugle pellets machine

Raw material: Wheat Flour

Machine material: SUS304

Electric Parts brand:SIEMENS

Product: Fried Bugles,Corn chips,Nacho chips

Fried bugle pellets machine photo

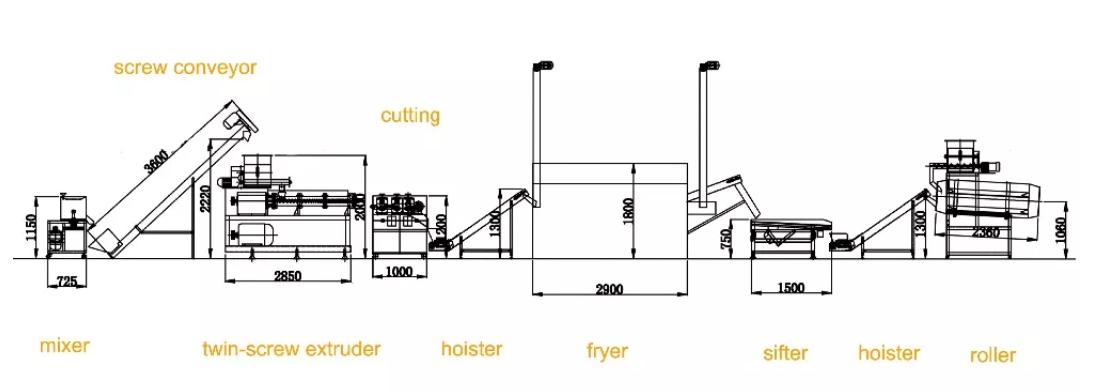

Fried bugle pellets machine layout

Product parameter:

There are three kind of capacity of fried bugles machine.

Model | Capacity | Power | Work area |

SLG65 | 120-150KG/H | 120KW | 100㎡ |

SLG70 | 220-250KG/H | 150KW | 120㎡ |

SLG85 | 350-400KG/H | 200KW | 150㎡ |

Cutter for Different shapes:

Product features:

The fried bugles machine can produce different shapes of fried snack food with various shapes of mould.

*The high automation machine requires easy operation.

*The twin screw extruder is durable for long time usage.

*The dryer has multiple layer which saves much space in factory.

*The PLC control banal help workers control each machine easily.

*The stainless steel material ensuring high quality machine.

*The flavoring machine can spray oil, sugar, honey, seasoning powder.

*The self cleaning tech without disassembling the machine.

Application:

The fried bugle machine can produce fried bugle and other shapes of snack food.

Service:

*Consultation service before, during,and after sales;

*Project planning and design service;

*Debugging of equipment until everything is functional;

*Management of equipment' long distance shipping from seller's factory to the named place by buyer;

*Training of equipment maintenance and operating personally;

*New production techniques and formulas;

*Provide 1 year complete warranty and life-time maintenance service.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible