Kurkure Cheetos Machine

Kurkure Cheetos Machine Features:

The kurkure cheetos machine line includes mixing, extruding, cutting, drying, flavoring parts. This machine line can produce high quality kurkure cheetos snack food with following highlights:

1. Stainless steel 304 material for the whole machine line. It ensures the high quality of the machine line.

2. Durable win screw gives the machine best performance.

3. High automation machine requires easy operation.

4. Self cleaning without disassembling.

Kurkure Cheetos Machine

Raw material:Corn grits

Product: Kurkures, Nik naks, Cheetos

Capacity:120kg/hour, 240kg/hour,360kg/hour and 480kg/hour

Machine material: SUS304

Screw Material: 38CrMoAl, Alloy steel

Kurkure Cheetos Machine Description:

The kurture cheetos machine is a made by a special kind of extruder. The kurkure cheetos machine uses extruder equipped with two rotary plates for squeezing and twisting the raw material. Then the extruder makes the curl shapes of the food. Flavored with seasoning powder, the kurkure cheetos is tasty and welcomed by the young.

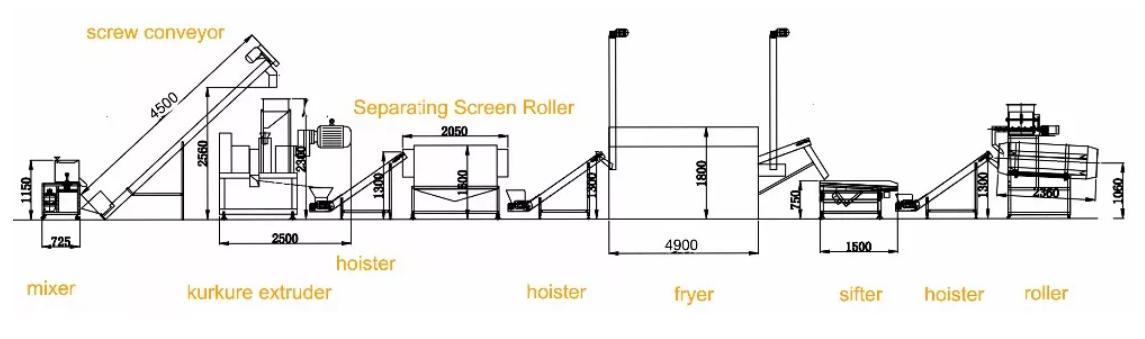

Kurkure Cheetos Machine Photo:

Kurkure Cheetos Machine Layout

Product Parameters:

The parameter of the kurkure cheetos machine:

Model | Install Power | Real Power | Capacity | Dimension | Area | Delivery |

DLG76 | 80KW | 55KW | 120kg/h | 20x 3.0 x 3.0 | 100m³ | 30 |

DLG76-II | 130KW | 90KW | 240kg/h | 28x 3.0 x 3.0 | 120m³ | 30 |

DLG76-III | 180KW | 120KW | 360kg/h | 35x 3.0 x 3.0 | 150m³ | 30 |

Product Sample:

Here are some samples of products produced by kurkure cheetos machine.

Application and After-Sales Service:

Application:

The kurkure cheetos machine can be used to produce cheetos kurkure snack food.

Service:

Before Sales:

1. We provide the drawing design according to customer workshop

2. We provide the formulation

3. We provide the cost analysis

4. We trail ran Pet Food Machine for customers

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Provide the upgrade on machines

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible