Hot sale fish food pellet processing line

This how t sale fish food processing line is increasing and have a big market.Meanwhile it has a tendency of commericalization and formalization.Full automation control, high production efficiency, it is the best choice for medium and big sized feed mills and breeding farms. This production lines with different capacities can also available to meet customers’ specific demands.

Pet Food Machine Description:

The Pet food machine can produce different kinds of pet food like: Dog food, cat food and other animal food. The pet food machine also name dog food machine, cat food machine and animal feed machine.This machine is suitable for Pet food factory.

Pet Food Machine Features:

Our Pet Food Machine the characteristics of small floor area, flexible placement, easy operation, low energy consumption and large output. A variety of grains can be used as raw materials to produce different dog food.

From the raw material to the final product packed in bags the whole process is automatically.

1. It can produce the pet food contains high Protein (60%-70%)

2. High automatically (just need 2-3 operators)

3. PLC control

4. Product Digestibility can reach 70%

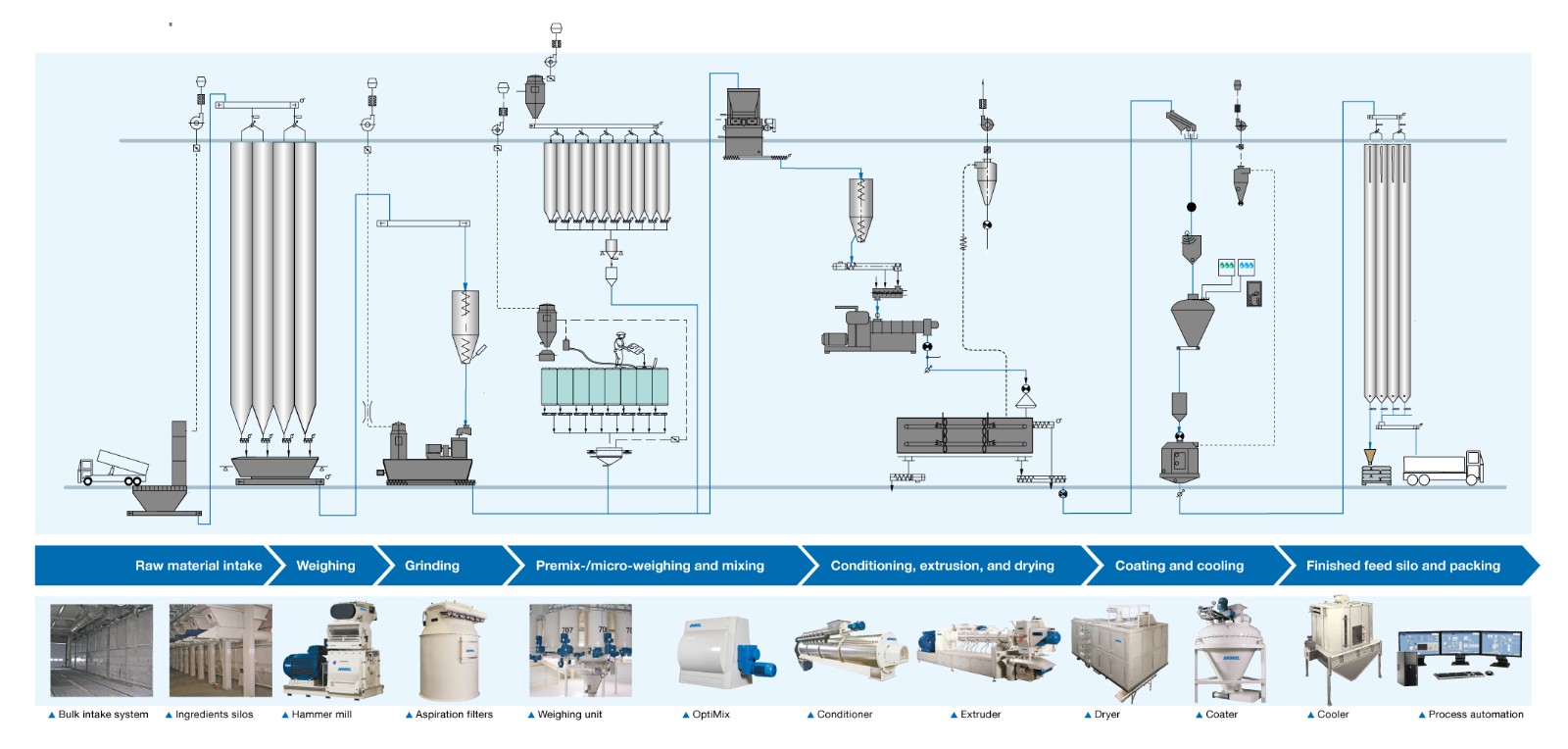

The whole pet food processing line picture:

The process of the pet food Machine:

1. Mix Raw Material

2. Extruding

Extrude the raw material by Twin-Screw Extruder. All raw material is processed in high temperature (140-160℃), High pressure(3-6Mpa)

3. Drying

Dry the Pet food In the continuous multi-Layer Dryer. The drying temperature about 120℃, drying time about 20-30 minutes. Reduce the moisture to about 12%

4. Flavoring

To spray oil and seasoning Powder on the surface of the pet food

5. Cooling

In the cooler to reduce the pet food temperature to 40℃

6. Packing

The pet fish food sample pictures:

Product Parameters:

Model | Install Power | Real Power | Capacity | Dimension | Size of workshop |

SLG65 | 70KW | 50KW | 120-150kg/h | 20x 2.0 x 3.0 | 150 |

SLG70 | 110KW | 80KW | 250-300kg/h | 25x 2.0 x 3.0 | 150 |

SLG85 | 200KW | 160KW | 500-600kg/h | 32x 2.0 x 4.0 | 200 |

SLG95 | 220KW

| 155KW

| 1000-1200kg/h | 40x 2.0 x 5.5 | 200 |

SLG120 | 280KW

| 195KW

| 2000-2500kg/h | 45x 2.0 x 7.0 | 250 |

Services

Before sales:

1).Provide the free consultation of the equipment.

2).Provide the standard device and the flow chart.

3). According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment..

During sales:

1).Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2).Welcome to visit our factory or the domestic clients' factory.

3).Inspect the machine before leaving the factory.

After sales:

1).Oversea install and debug the equipment.

2).Train the first-line operator.

3).Provide the basic formula.

Certificiations

As a professional dog food extruder manufacturer,Jinan Saibainuo Co,Ltd has exported the dog food extruder with CE certification to more than 80 countries and regions,such as South Africa ,India,Malaysia,Indonesia,Brazil and so on.Some of dog food food extruder customers become our agents in this area.We hope to have long friendly business relationship with more customers from all over the world in the future.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible