Dog Chews Extruder Machine

1. It can produce the dog Chews contains high Protein (60%-70%)

2. High automatically (just need 2-3 operators)

3. PLC control

4. Product Digestibility can reach 70%

5. It can use Fresh meat as the raw material.

6. It can produce single color and double color dog Chews

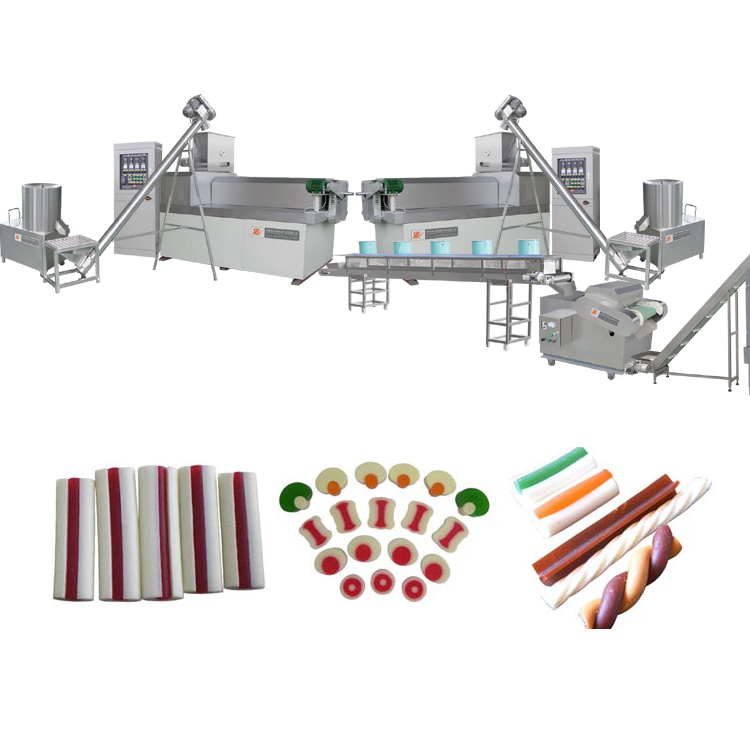

Dog Chews Extruder Machine

Product introduction:

The dog chews extruder machine can produce different shapes pet chews and dog chews. It use the meat meal, grains flour, starch as the main raw material. It can produce both single color and double color dog chews food.

Product parameter:

The dog chews extruder machine have some models for customers to choose.

Model | Install Power | Real Power | Capacity | Dimension(M) | Size of workshop(㎡) |

DLG100 | 70KW | 50KW | 100-120kg/h | 20x 2.0 x 3.0 | 100 |

DLG120 | 110KW | 80KW | 200-220kg/h | 25x 2.0 x 3.0 | 120 |

DLG150 | 200KW | 160KW | 350-400kg/h | 32x 2.0 x 4.0 | 150 |

Product sample:

Product features:

The Dog Chews Extruder Machine is high automatically work

From the raw material to the final product packed in bags the whole process is automatically.

1. It can produce the dog Chews contains high Protein (60%-70%)

2. High automatically (just need 2-3 operators)

3. PLC control

4. Product Digestibility can reach 70%

5. It can use Fresh meat as the raw material.

6. It can produce single color and double color dog chews

Service:

Before Sales:

1. We provide the drawing design according to customer workshop

2. We provide the formulation

3. We provide the cost analysis

4. We trail ran Pet Food Machine for customers

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Provide the upgrade on machines

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Certificates:

Related Products

Related News

Submitted successfully

We will contact you as soon as possible