Panko Breadcrumb Machine

Main raw material: Corn flour and wheat flour

Product: Panko Bread crumb

Capacity:150kg/hour, 250kg/hour and 500kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Product description:

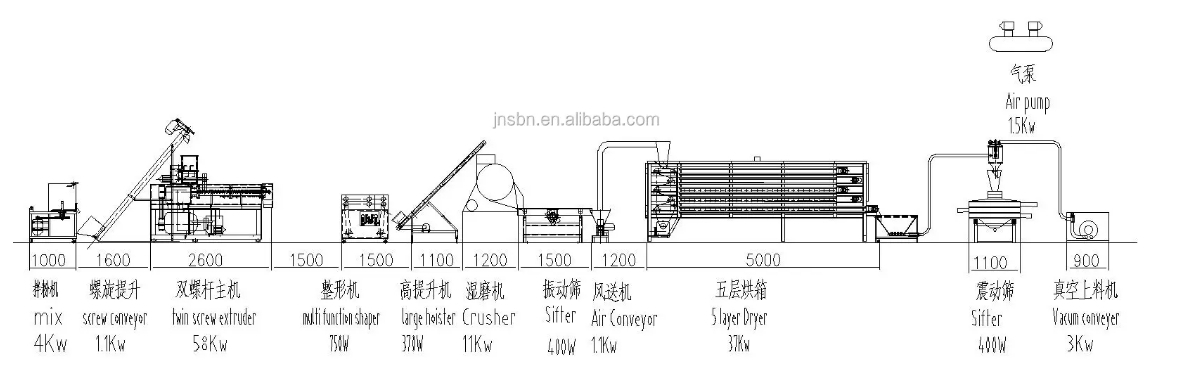

With high automation technology, panko machine can produce different size of bread crumbs with easy operation for workers. The bread crumb can be used widely in food plant, thus this panko machine is welcomed by customers in the past decade years. The process of the panko machine is mixing, extruding, shaping, milling, sifting, drying and sifting. After the whole process, the panko bread crumb will be produced well and packed in bags.

Panko Machine

Main raw material: Corn flour and wheat flour

Product: Panko Bread crumb

Capacity:150kg/hour, 250kg/hour and 500kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Panko breadcrumb machine photo:

Product parameter:

There are three kind of capacity of panko machine.

Model | Install Power | Real Power | Capacity | Dimension |

SLG65 | 80KW | 55KW | 140-150kg/h | 20x 2.0 x 3.0 |

SLG70 | 120KW | 85KW | 240-250kg/h | 25x 2.0 x 3.0 |

SLG85 | 180KW | 130KW | 450-500kg/h | 32x 2.0 x 5.0 |

Panko machine process:

The process of panko machine are as follows:

Mixing: To mix the raw material evenly.

Extruding: Extrude and cook raw material into different size and shapes.

Milling: Crush the cooked material in to small crumbs. There is a sieve inside. We can change different size sieve to produce different size of bread crumbs.

Drying: There are multiple layers inside, thus it can save space and energy. It is electricity heating.

Sifting:To separate the bread crumbs into different kinds of size. There have different size of sieves inside.

Application:

The panko machine produces different size of bread crumb which can be used for food plant.

Services:

*Consultation service before, during,and after sales;

*Project planning and design service;

*Debugging of equipment until everything is functional;

*Management of equipment' long distance shipping from seller's factory to the named place by buyer;

*Training of equipment maintenance and operating personally;

*New production techniques and formulas;

*Provide 1 year complete warranty and life-time maintenance service.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible