Puff Snack Making Machine

Puff Snack Machine Features:

Our Puff Snack Making Machine can produce the Puff snacks and corn filling snacks.

The main raw material is Corn flour, rice flour, wheat flour, sugar and oil

From the raw material to the final product packed in bags the whole process is automatically.

1. Machines are High automatically (just need 2-3 operators)

2. Machine temperature and speed is automatic control

3. It produce the Corn puff snacks and Core filling snacks

4. The Puff snack food machine is PLC control, touch screen operate

5. Big output (From 100kg/hour to 500kg/hour)

Puff Snack Machine Features:

Our Puff Snack Making Machine can produce the Puff snacks and corn filling snacks.

The most important uncooked fabric is Corn flour, rice flour, wheat flour, sugar and oil

From the uncooked fabric to the very last product packed in luggage the entire technique is automatically.

Puff snack Machine, Core filling Puff Snack machine

Product: Puff snack, Core filling snack

Raw material: Corn flour, rice flour, wheat flour, sugar and oil

Machine material: SUS304

Motor Brand: SIEMENS

Machine Operation: Automatic Control

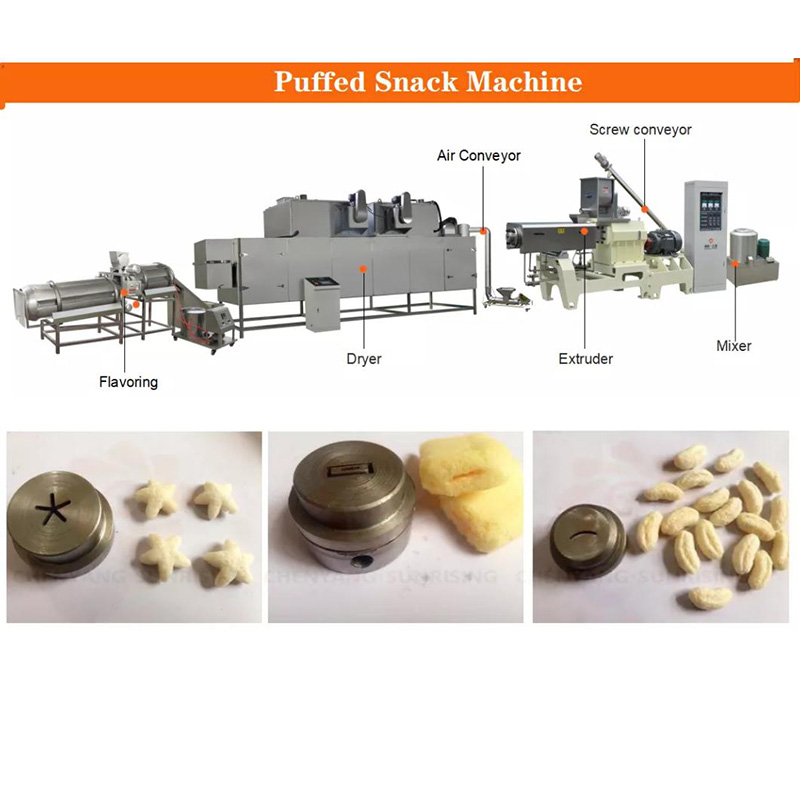

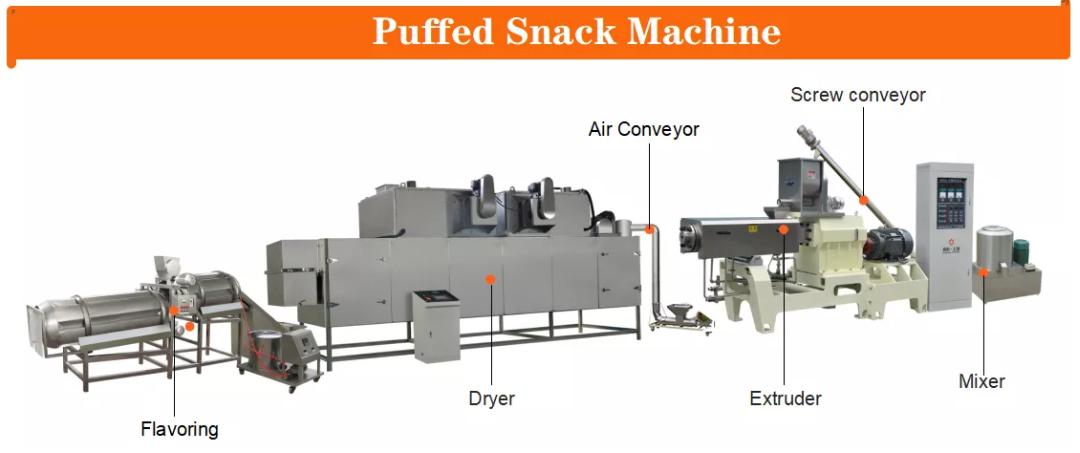

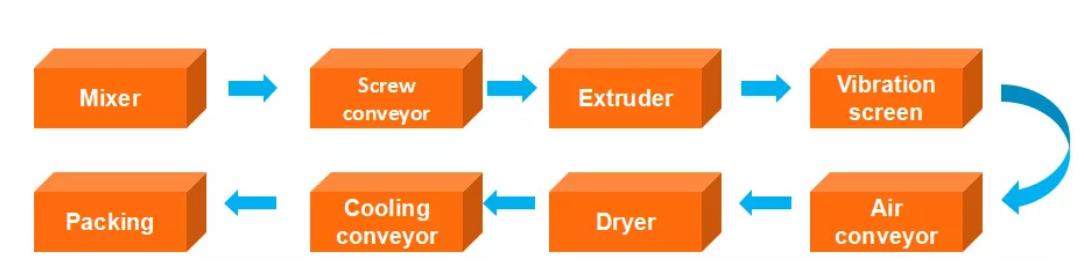

The Puff Snack Making Machine flow chart:

Different Mould to make different shapes Puff snack:

Puff Snack Making Machine Sample:

Core filling Snack food sample:

Puff Snack Making Machine Parameters:

| Model | Install Power | Real Power | Capacity | Dimension(M) | Size of workshop(㎡) |

| SLG65 | 70KW | 50KW | 120-150kg/h | 20x 2.0 x 3.0 | 100 |

| SLG70 | 110KW | 80KW | 220-250kg/h | 25x 2.0 x 3.0 | 120 |

| SLG85 | 180KW | 140KW | 450-500kg/h | 32x 2.0 x 4.0 | 150 |

Application and After-Sales Service:

The Fish feed Machine is used for fish feed production industry.

“Saibainuo Machinery” provide the great Service to help our customers set up their project

Before Sales:

1. We provide the layout design according to customer workshop dimension

2. We provide the formulation of the fish feed

3. We provide the cost analysis to help customer check their market

4. We trail ran fish feed machine in our factory for customers before shipment

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Help customer to upgrade their machine in the future

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible