Baby Food Machine

Main raw material: Corn, rice, wheat, milk and other grains flour

Product: Baby food, Nutrition powder

Capacity: 150kg/hour,260kg/hour, 600kg/hour and 1000kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Product feature:

*Durable screw on the extruder guarantee long usage life.

*Stainless steel material ensuing high quality of the baby food machine line.

*Heating and cooling can be controlled independently.

*Self cleaning without disassembling.

*High automation machine requires easy operation.

Main raw material: Corn, rice, wheat, milk and other grains flour

Product: Baby food, Nutrition powder

Capacity:150kg/hour,260kg/hour, 600kg/hour and 1000kg/hour

Machine material: SUS304

Electric parts brand: SIEMENS

Baby Food Machine Description:

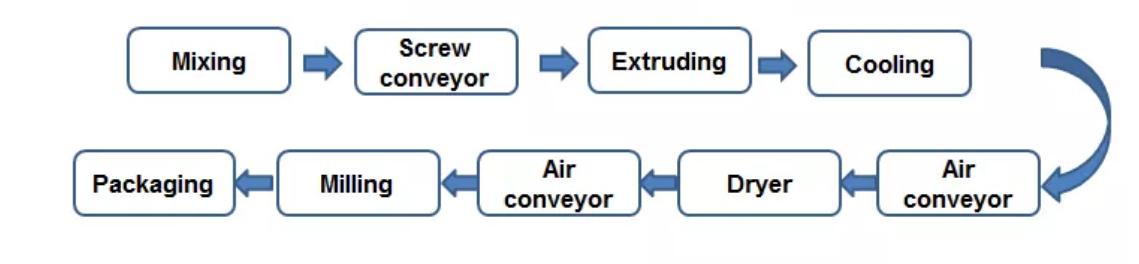

Baby food machine is used to produce uses rice, corn, beans and all kinds of grains as raw materials. Through the process of extruding, crushing, drying, and mixing, it could produce many kinds of nutrition powder, such as baby rice powder, sesame paste, beans powder and so on. The baby food machine is easy to operate, it can save energy without leak of powder dust. Thus it is welcomed by customers.

Baby Food Machine Photo:

Product sample:

Here are some sample of baby food machine products.

Product feature:

*Durable screw on the extruder guarantee long usage life.

*Stainless steel material ensuing high quality of the baby food machine line.

*Heating and cooling can be controlled independently.

*Self cleaning without disassembling.

*High automation machine requires easy operation.

Baby Food Machine Parameter:

There are three kind of capacity of baby food machine for customers to choose.

Model | Install Power | Real Power | Capacity | Dimension |

SLG65 | 79KW | 55KW | 150KG/H | 20x 2.0 x 3.0 |

SLG70 | 110KW | 72KW | 250KG/H | 23x 2.0 x 3.0 |

SLG85 | 190KW | 130KW | 500KG/H | 30x 2.0 x 3.5 |

SLG95 | 250KW | 170KW | 1000KG/H | 40x 2.0 x 5.0 |

Application:

The baby food machine can produce baby food powder and other nutrition powder for all ages of people.

Services:

Before Sales:

1. We provide the drawing design according to customer workshop

2. We provide the formulation

3. We provide the cost analysis

4. We trail ran Pet Food Machine for customers

5. We provide the specification of machines

After-sales Service

1. Engineer to customers’ factory to install the machine

2. Engineers train the customers operation and maintenance

3. Develop the formulation to customers

4. Provide the upgrade on machines

5. Guide the customers by Email and Call

6. Provide the good quality low cost spare parts to customers.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible